Wherein I Board a Real Boat

Sort of neglectful here lately. We’ve had a spate of really nice weather, and I’ve been out enjoying it as much as I can. there have been a few bloggable events.

Do any of you follow Discover’s The Deadliest Catch (I don’t, really)? One of my clients (the same client that sent me to Adak, Alaska a few years ago) operates longliners and catcher-processors in the Alaska crab and groundfish fisheries, and celebrated the 20th anniversary of their flagship vessel last week with a luncheon at dockside. Here is the ship, which I photographed a few weeks ago as I paddled my kayak in the Ship Canal near Ballard (Click any photo to enlarge):

I arrived at the luncheon just as the vessel’s captain was about to conduct a tour of the ship, and I hustled up the gangplank. I’d been on the boat before for a short tour and to work on some onboard computers, but a tour given by the 15-year captain was a treat. The Starbound is a catcher-processor, meaning that it has a full fish-processing factory below decks to process its catch. Below, left is the bridge, bristling with electronics both for running the ship and for looking for fish. First question: where’s the wheel? Jack Sparrow would be lost here.

Below, center is a typical crew quarters. Fully crewed, the vessel houses 110 people. There are two more bunks to my left, and this unit shares a bathroom with a similar unit. Since they work 12 - 14-hour shifts, I don’t imagine it’s that often that all 5 or 6 sailors are in the room at the same time.

Below, right is the laundry room. There are two more washing machines and a dryer or two behind me.

|

|

|

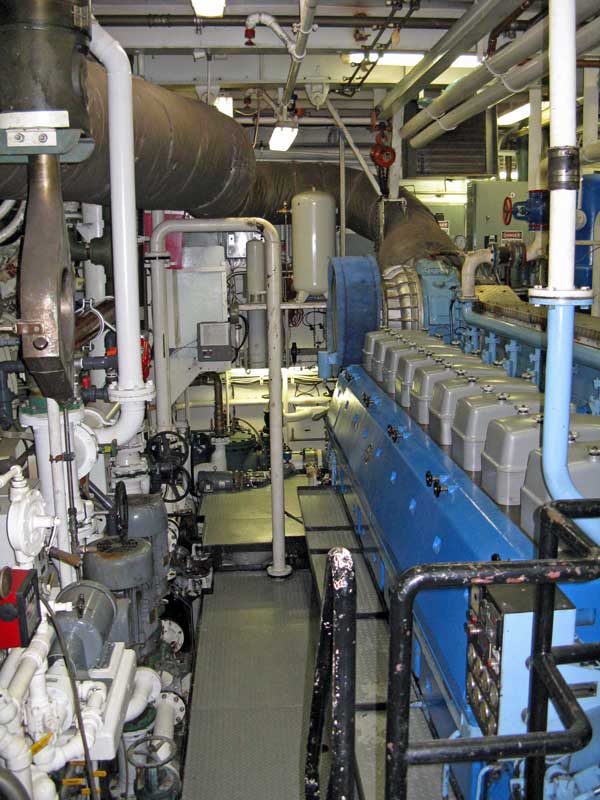

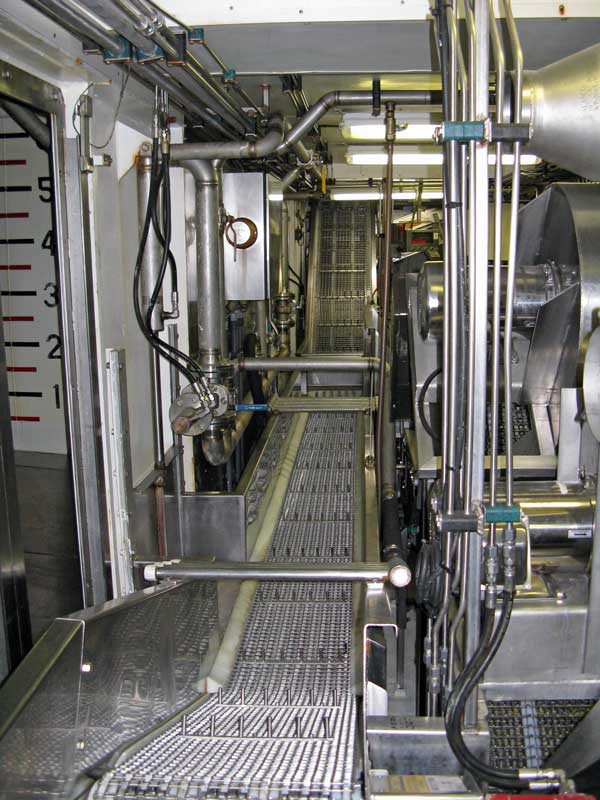

More pics - Below, left is the boat’s main engine. 9 cylinders (spare piston hanging in the left of the photo) and, I believe he said 750 hp. Next pic to the right is the deck facing the stern, where the net is hauled in if they’re fishing for cod or pollock. I think he said that each load from the net is 9 tons. The fish travel through a hatch on this deck down to the factory, where they start their journey to fish-and-chip land on the conveyor, next right. After they’ve been cleaned and fileted, they are flash-frozen in the ingots on the far right. The end product is a 150-lb brick of frozen fish ready for delivery to the wholesaler.

|

|

|

|